Dear Colleagues,

We all believe that ZT value could be extended well beyond the unity, opening a big market for thermoelectric energy harvesting. However, what we need first is an unquestionable and accurate measurement of ZT value in a medium-high temperature range. Measurement of electrical resistivity, Seebeck coefficient, and thermal conductivity separately leads to unacceptable uncertainty in calculated ZT value, as was demonstrated by well-known international round-robin tests. At ICT2014 we presented a ZT-Scanner that allows automated direct measurement of ZT value simultaneously with all its components in the temperature range of 300-700K. The direct measurement of ZT is based on Harman setup. We introduced a novel calibration procedure to eliminate the influence of the parasitic thermal exchange between the sample and its environment during the measurement. This so called 2SSC (Two Sample System Calibration) procedure ensures an unprecedented ±1% accuracy for ZT value and the values of its components. The ZT-Scanner and 2SSC procedure received international recognition and our presentation was awarded the Best Paper of ICT2014. It can be downloaded from www.temte.ca/ZT_Accuracy.html. ZT-Scanner is commercialized by TEMTE Inc. Detailed information is available at www.temte.ca.

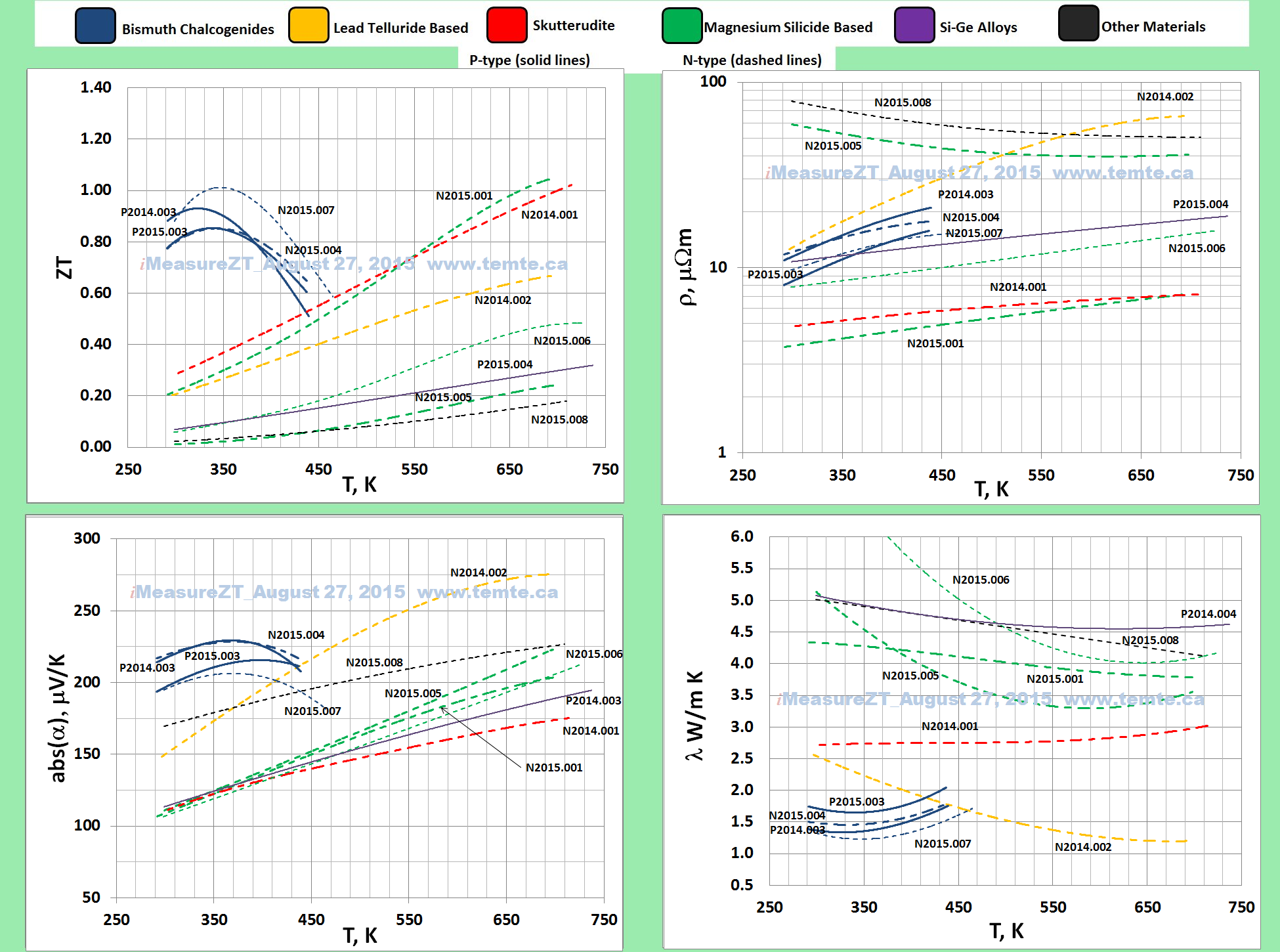

Since ZT-Scanner is a new product, it may not yet be accessible to all members of the thermoelectric community. However, because we recognize the importance of measuring ZT value accurately, we’ve launched a new service called “iMeasureZT”. TEMTE Inc. offers complete thermoelectric characterization of your sample in the temperature range 300-700K with a decrement of 20K. The full report is presented in PDF format and includes 80 experimental values for ZT, Seebeck coefficients, electrical and thermal conductivities to be provided to the sample owner. The tendency lines without experimental points on the figures cumulating all tested samples will also be provided to all visitors of the web site www.temte.ca. Because of potential problems related to the strong competition in this field, the sample owner can identify the measured sample on cumulative figures by assigning it a nickname. Some information about the sample nature is required. The exact composition is not mandatory, but identification of material group such as skutterudite, half-heusler compound, SiGe-alloy, or other is required. We will ensure the detailed experimental data will not be shared with a third party. After the measurement, the sample could be either stored or destroyed in our facility, or sent back depending on your preference.

At the minimal price of 100$ we provide an affordable access to accurate ZT measurements for all members of the thermoelectric community. This price covers only the operational costs and applies to one sample per year. Please contact us for a special agreement if you need more measurements.

We're confident that the iMeasureZT service will move the thermoelectric industry forward by delivering public access to the maximum attainable ZT values accurately measured on one system. We also encourage a discussion of the results for the Linkedin members in the recently created group with the same name iMeasureZT.

iMeasureZT service is simple to use. Just fill out the Application Form and send it to us accompanied with your sample and a check for $100 payable to TEMTE Inc. with a reference to ZT measurement. PayPal account holders are encouraged to make a money transfer to the email paypal@temte.ca instead of sending a check.

We recommend samples with rectangular cross sections 5×5 mm2 and from 3 to 6 mm long; however cylindrical samples with equivalent section can also be used. Two opposite sides of your sample will be subjected to electrolytic Ni deposition (about 5 micrometers) then silver contact paste and copper contact plates will be applied. All assembly will be cured first in air for 1 hour at 70°C and then under vacuum for 2 hours at 400°C. Please specify if your sample already has metal coating on the contact surfaces and doesn’t need Ni deposition. Also specify the recommended direction of measurement if your sample is anisotropic. During the measurements your sample will be gradually heated inside the vacuum chamber from 300K up to 700K with an increment of 20K. If you have any questions about specific sample preparation or measurement procedure, please contact us at info@temte.ca.

Below you can find the latest iMeasureZT Report. We will periodically update the Report replacing old results by the new ones, however permanently keeping the best results for each material group.